Have you ever wondered if a simple piece of technology could have a significant impact on sustainability in the supply chain? Well, let me introduce you to the world of dc servo drives. These little devices might not seem like much at first glance, but they hold the potential to revolutionize industries and make our planet greener.

The Marvels of DC Servo Drives

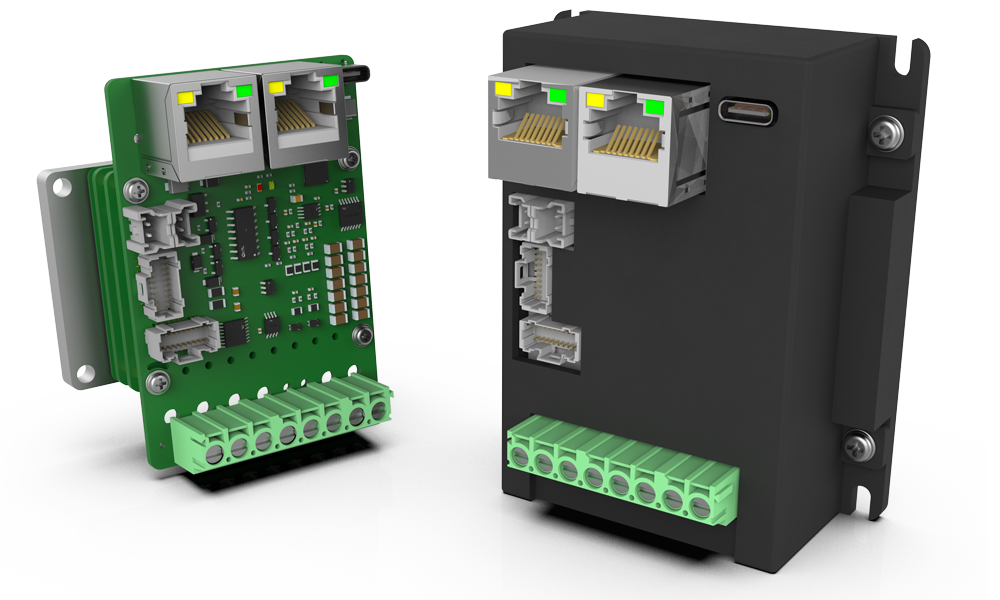

DC servo drives are compact electronic components that control and regulate the speed and position of machinery. They work by converting direct current (DC) into alternating current (AC), allowing for precise control over motor movements. This means that machines equipped with these drives can operate more efficiently, reducing energy consumption and minimizing waste.

Imagine a factory where every machine is powered by a DC servo drive. The motors would run smoothly without unnecessary friction or overheating, resulting in less wear and tear on equipment. Not only would this extend their lifespan, but it would also reduce maintenance costs and decrease the need for replacements – ultimately leading to fewer resources being consumed.

The Leading Role of Leadshine

In the realm of DC servo drives, one company stands out: Leadshine. With their cutting-edge technology and commitment to sustainability, they have become pioneers in this field. Their drives are known for their high precision and reliability while maintaining low power consumption.

Leadshine’s dedication to sustainable manufacturing practices extends beyond just producing efficient products; they also prioritize responsible sourcing of materials. By partnering with suppliers who adhere to strict environmental standards, Leadshine ensures that their entire supply chain aligns with sustainable principles.

A Touchscreen Revolution: HMI Touchscreens

No discussion about modern industrial automation is complete without mentioning hmi touchscreens – another technological marvel contributing to sustainability. These user-friendly interfaces allow operators to control and monitor machinery with ease, reducing the risk of human error and optimizing energy usage.

Imagine a factory floor where every machine is equipped with an HMI touchscreen. Operators would have real-time access to data on energy consumption, allowing them to identify inefficiencies and make adjustments accordingly. This level of transparency empowers companies to optimize their processes continually, resulting in reduced waste and increased overall efficiency.

The Bottom Line

DC servo drives, such as those offered by Leadshine, along with the integration of HMI touchscreens, hold immense potential for revolutionizing industries while promoting sustainability in the supply chain. By improving energy efficiency, reducing waste, and optimizing operations through advanced technology, we can pave the way towards a greener future.