In today’s rapidly evolving technological landscape, one innovation that is making waves in the manufacturing industry is Liquid Silicone Rubber (LSR) molds. These cutting-edge molds have revolutionized the production process by offering numerous advantages over traditional molding techniques.

The Advantages of LSR Molds

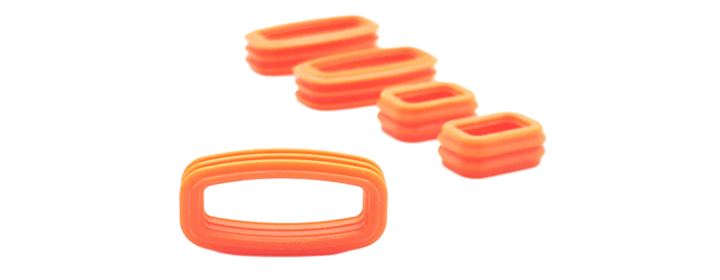

lsr molds are known for their exceptional precision and versatility. They allow manufacturers to create complex designs with intricate details, ensuring consistent quality and accuracy in every product. Additionally, these molds offer excellent heat resistance and durability, making them ideal for applications that require high-performance materials.

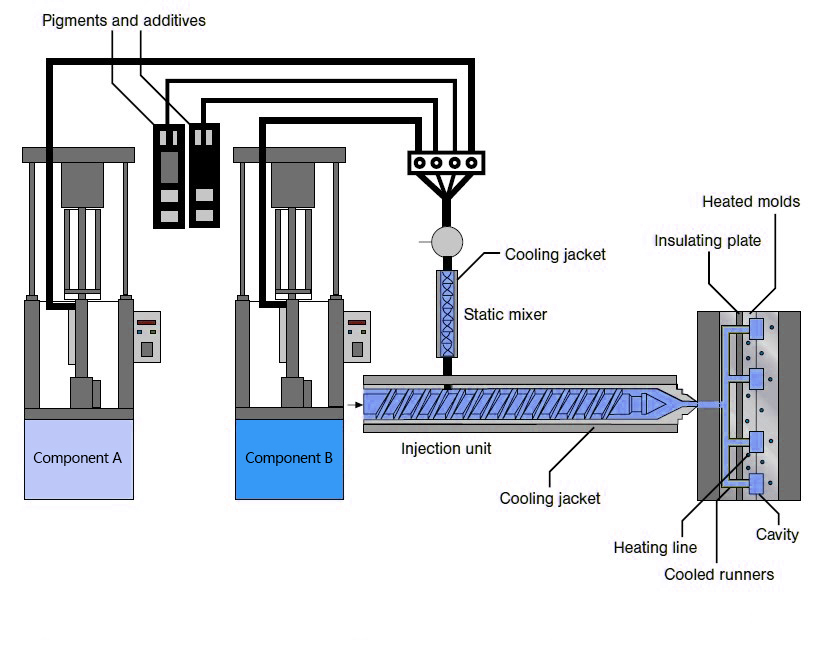

Furthermore, LSR molds enable faster production cycles due to their ability to cure quickly at lower temperatures. This not only increases efficiency but also reduces energy consumption during the manufacturing process. With shorter lead times and improved productivity, businesses can meet market demands more effectively.

JVTECH: A Leader in LSR Mold Technology

When it comes to pioneering advancements in LSR mold technology, JVTECH stands out as a leading company based in Kansas. With years of experience and expertise in this field, JVTECH has been instrumental in developing innovative solutions that cater to various industries’ needs.

JVTECH’s state-of-the-art facilities house advanced machinery capable of producing high-quality LSR molds efficiently. Their team of skilled engineers works closely with clients to design custom-made molds tailored specifically to their requirements. By leveraging cutting-edge technologies and extensive knowledge, JVTECH ensures optimal performance and customer satisfaction.

The Power of Toy Molding with LSR

Toys play an essential role in children’s development while providing entertainment and joy. The use of LSR molds has significantly enhanced toy manufacturing processes by enabling the creation of safe and durable products. LSR’s flexibility and softness make it an ideal material for producing toys with intricate designs, vibrant colors, and smooth textures.

Moreover, LSR molds offer excellent resistance to extreme temperatures and chemicals commonly found in household environments. This ensures that the toys remain intact even under rigorous play conditions while meeting stringent safety standards.

In Conclusion

LSR molds have revolutionized the manufacturing industry by offering unparalleled precision, versatility, and efficiency. Companies like JVTECH in Kansas are at the forefront of this technological advancement, providing custom-made solutions tailored to various industries’ needs. From toy molding to high-performance applications, LSR molds continue to drive innovation and shape the future of manufacturing.