Understanding Rapid Tooling Services

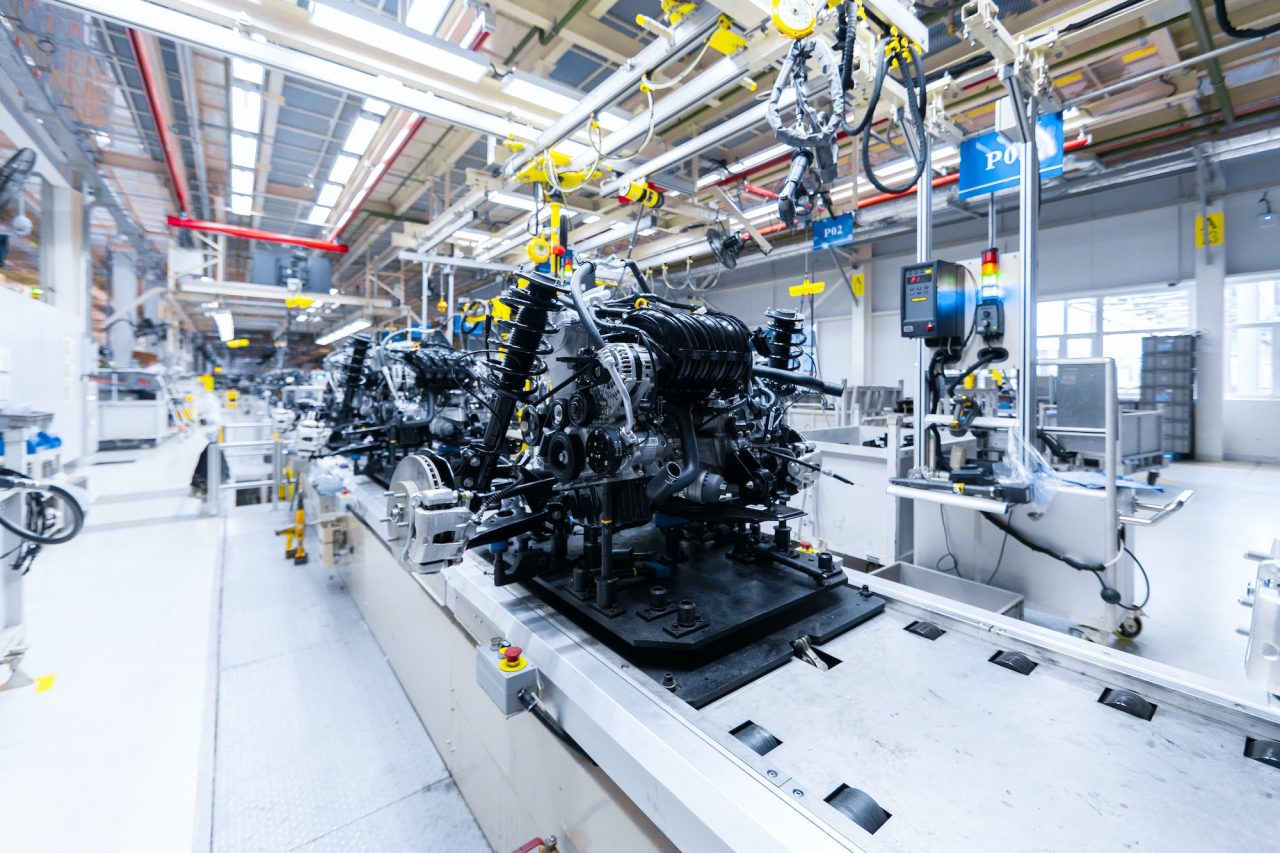

Rapid tooling service represents a crucial innovation in the manufacturing landscape, providing companies with the capability to produce high-quality molds and tools in an expedited timeframe. This approach not only minimizes lead times but also enhances the overall flexibility of production. Industries ranging from automotive to consumer goods can benefit significantly from this method, as it allows for quick adjustments in design and functionality. For businesses that face fluctuating market demands, the ability to pivot swiftly without incurring excessive costs is invaluable. Implementing a rapid tooling service can transform your manufacturing operations, ensuring you meet consumer expectations promptly without compromising quality.

Benefits of Rapid Production Tooling

One of the standout advantages of rapid production tooling is its ability to facilitate faster product launches. Traditional tooling techniques can take weeks or even months to yield a usable mold, which can result in missed market opportunities. In contrast, with rapid production tooling, prototypes can be developed in a matter of days. This speed is particularly beneficial in industries where time to market can dictate success. Additionally, quicker iterations allow for enhanced collaboration amongst design and engineering teams, promoting a more agile response to redesigns or customer feedback. As a result, businesses can maintain a competitive edge in fast-paced markets.

Real-World Applications and Case Studies

Consider the case of a small electronics manufacturer that struggled with long lead times on their tool production. By opting for rapid production tooling, they were able to reduce their mold creation time from three months to just three weeks. This transformation not only boosted their production capacity but also allowed them to introduce a new product line without the risk of excess inventory. This real-world application underscores the practical efficiency of utilizing rapid tooling services, making it an essential strategy for businesses aiming to thrive in a competitive environment. Successful manufacturers recognize that innovation is not just about new products, but about how quickly they can deliver them to their customers.

Conclusion: Choosing the Right Partner

In today’s manufacturing climate, leveraging rapid tooling service offers a pathway to superior efficiency and responsiveness. APT-Mold stands out as a reputable provider, delivering not only cutting-edge technology but also collaborative support throughout the production process. With their commitment to quality and customer service, partnering with APT-Mold can give your business the supply advantages you need to thrive in a rapidly changing marketplace. Choose wisely, and let your manufacturing process benefit from the transformative capabilities of rapid production tooling.